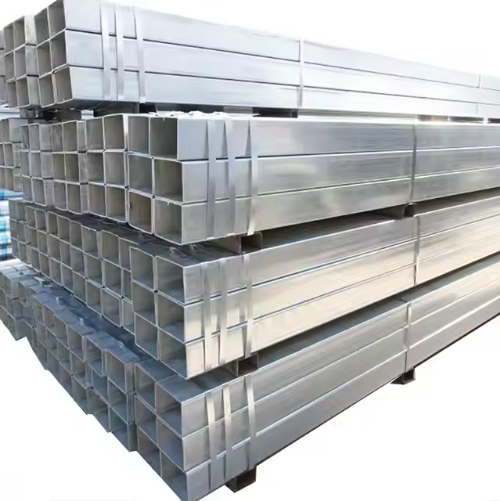

Youfa Q235B galvanized square tubes, genuine Grade A, electro-galvanized with a matte finish, for precision instrument frames.

Category:

Summary description:

Keywords:

Details

Youfa Q235B galvanized square tubes, bearing the hallmark of genuine Grade A quality, electro-galvanized with a sophisticated matte finish, and specifically engineered for precision instrument frames, represent the pinnacle of reliability and precision in industrial materials. These tubes, backed by the esteemed Youfa brand, have become the preferred choice for manufacturers and engineers seeking components that can meet the exacting demands of precision instruments, where even the smallest deviation can compromise performance.

At the core of these tubes’ excellence is the Q235B material, a carbon structural steel celebrated for its exceptional mechanical properties. Q235B steel boasts a yield strength of 235 MPa, striking an ideal balance between rigidity and ductility—two qualities that are paramount in precision instrument frames. Rigidity ensures that the frame maintains its shape under the weight of sensitive components, preventing misalignments that could affect the instrument’s accuracy. Ductility, on the other hand, allows for intricate machining and forming, enabling the creation of complex frame designs that accommodate the unique layouts of precision instruments, such as spectrometers, microscopes, and laser measuring devices. This versatility in processing is further enhanced by Q235B’s excellent weldability, ensuring that components can be joined seamlessly without weakening the structure—a critical factor in frames that must maintain stability over extended periods of use.

The “genuine Grade A” designation is more than a quality label; it is a guarantee of consistency, reliability, and adherence to the highest industry standards. Youfa, a renowned name in steel manufacturing, subjects its Grade A products to rigorous quality control measures, from the selection of raw materials to the final inspection of finished tubes. Each Q235B galvanized square tube undergoes meticulous testing to ensure dimensional accuracy, uniform wall thickness, and absence of defects such as cracks, pits, or uneven galvanization. For precision instrument frames, where even minor imperfections can lead to vibrations, misalignments, or electrical interference, this level of quality assurance is indispensable. Grade A certification also ensures that the tubes meet strict tolerances for straightness and squareness, with deviations measured in microns—critical for frames that must align with optical components or electronic sensors with submillimeter precision.

Electro-galvanization, the process used to coat these square tubes, is chosen for its ability to deliver a thin, uniform, and tightly adherent zinc layer—qualities that are essential for precision applications. Unlike hot-dip galvanization, which produces a thicker, rougher coating, electro-galvanization uses an electrochemical process to deposit zinc ions onto the steel surface, resulting in a smooth, consistent finish with precise thickness control (typically 5–20 microns). This thin coating is ideal for precision instrument frames, where excess material could interfere with tight clearances between components. The electro-galvanized layer provides excellent corrosion resistance, protecting the steel from moisture, humidity, and chemical exposure in laboratory or industrial environments. For instruments used in cleanrooms or medical facilities, where hygiene is critical, the non-porous nature of the electro-galvanized coating prevents the accumulation of dust, bacteria, or contaminants, ensuring compliance with strict cleanliness standards.

The matte finish of these tubes is a deliberate design choice that enhances their suitability for precision instrument frames in multiple ways. Unlike glossy surfaces, which can reflect light and cause glare, the matte texture minimizes reflections—vital in instruments with optical components, such as microscopes or spectrometers, where stray light can distort measurements or obscure images. This anti-glare property also improves visibility for technicians working with the instruments, reducing eye strain during prolonged use. Additionally, the matte finish hides fingerprints, smudges, and minor scratches that are inevitable during assembly, handling, or maintenance, preserving the professional appearance of the instrument. For manufacturers of high-end precision equipment, where aesthetics are part of the product’s value proposition, this low-maintenance finish ensures that the instrument remains visually appealing throughout its lifecycle.

Precision instrument frames demand materials that can support sensitive components while minimizing vibrations and electromagnetic interference (EMI)—and Youfa Q235B galvanized square tubes excel in both areas. The inherent rigidity of Q235B steel, combined with the square cross-section, creates a stable platform that dampens vibrations caused by external factors (such as nearby machinery) or internal mechanisms (such as motors or pumps). This vibration damping is critical for instruments like atomic force microscopes or mass spectrometers, where nanoscale measurements can be disrupted by even the smallest movements. The electro-galvanized coating, while thin, also provides a degree of EMI shielding, protecting sensitive electronic components from external electromagnetic fields that could corrupt data or cause malfunctions. In instruments used in research laboratories or manufacturing facilities with high levels of electrical noise, this shielding adds an extra layer of reliability.

The square shape of these tubes offers practical advantages for precision instrument frame construction. Square tubes provide flat, uniform surfaces for mounting components, ensuring secure attachment with screws, brackets, or adhesives. This flatness is essential for aligning optical lenses, sensors, or circuit boards with the precision required for accurate instrument operation. The right-angle corners of square tubes also simplify the assembly of frame structures, allowing for straightforward joining of horizontal and vertical components without the need for complex fixtures or adapters. This ease of assembly reduces manufacturing time and minimizes the risk of alignment errors, ensuring that each instrument meets the same strict performance standards. For manufacturers producing instruments in small to medium batches, this efficiency in assembly translates to lower production costs and faster time-to-market.

Durability is another key attribute that makes these tubes ideal for precision instruments, which often have lifespans of 10 years or more. The electro-galvanized coating protects against corrosion in diverse environments, from the dry, air-conditioned labs of research facilities to the humid conditions of pharmaceutical cleanrooms. This resistance to rust and degradation ensures that the frame remains structurally sound, preventing costly failures or performance degradation over time. The Q235B steel’s high tensile strength also allows the frame to withstand mechanical stress from repeated use, such as opening/closing doors, adjusting components, or transporting the instrument. For field-deployed instruments, which may be subjected to rough handling or environmental extremes, this durability ensures reliable operation in challenging conditions.

The compatibility of these tubes with precision machining processes further enhances their value for instrument manufacturers. They can be easily cut, drilled, tapped, or milled to create custom holes, slots, or mounting points, allowing for precise integration with unique instrument designs. The uniform wall thickness and consistent material properties of Grade A tubes ensure that machining operations produce predictable, repeatable results—critical for maintaining tight tolerances across production runs. Whether creating a frame for a benchtop analyzer or a large-scale industrial metrology system, manufacturers can rely on these tubes to meet their exact specifications, reducing the need for post-machining adjustments or rework.

In summary, Youfa Q235B galvanized square tubes—with their genuine Grade A quality, electro-galvanized matte finish, and tailored design for precision instrument frames—represent a synergy of material science and engineering expertise. They combine the strength and stability of Q235B steel with the protective benefits of electro-galvanization, enhanced by a matte finish that addresses the unique challenges of optical and sensitive equipment. From minimizing vibrations and glare to ensuring corrosion resistance and precision alignment, these tubes meet the multifaceted demands of precision instrument manufacturing. Backed by Youfa’s reputation for quality and consistency, they provide manufacturers with a reliable, high-performance material that contributes to the accuracy, durability, and aesthetics of their instruments. For engineers and product designers seeking to elevate the performance of their precision equipment, these tubes stand as a testament to how thoughtful material selection can drive innovation in industrial design.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.