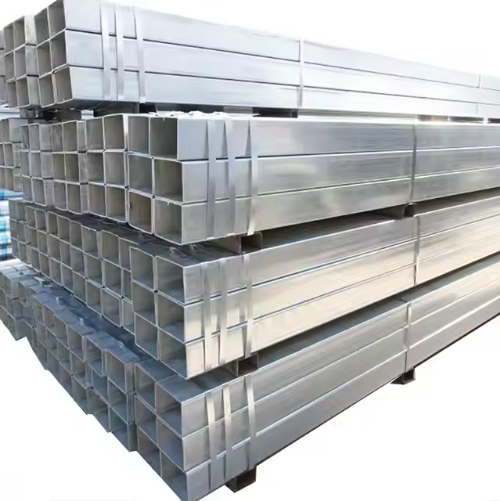

Environmental-friendly hot-dip galvanized square tubes, for marine engineering, 20-year rust prevention guarantee, preferred choice for outdoor projects.

Category:

Summary description:

Keywords:

Details

Environmental-friendly hot-dip galvanized square tubes, tailored for marine engineering with a 20-year rust prevention guarantee, stand as the preferred choice for outdoor projects, embodying a perfect blend of sustainability, durability, and performance. These tubes have redefined industry standards by addressing the unique challenges of harsh environments while aligning with global efforts toward eco-conscious construction practices.

At the core of their appeal is the environmental-friendly nature of their manufacturing process. Traditional galvanization methods often involve chemicals that pose risks to ecosystems, but these hot-dip galvanized square tubes utilize advanced, low-emission techniques that minimize environmental impact. The zinc used in the process is sourced from recycled materials, reducing the need for virgin ore extraction and lowering carbon footprints. Additionally, the galvanization process is designed to minimize waste, with excess zinc collected and reused, ensuring that resources are utilized efficiently. This commitment to sustainability extends beyond production: the tubes themselves are fully recyclable at the end of their service life, contributing to a circular economy and reducing construction waste. For projects aiming to meet green building certifications or adhere to strict environmental regulations, these tubes offer a responsible choice without compromising on performance.

Marine engineering presents some of the most demanding conditions for construction materials, with constant exposure to saltwater, humidity, and corrosive marine organisms. Environmental-friendly hot-dip galvanized square tubes are engineered to thrive in these environments, making them indispensable in marine applications. Saltwater, rich in chloride ions, is highly corrosive to unprotected steel, capable of causing rust and structural degradation within months. The hot-dip galvanization process forms a dense, metallurgically bonded zinc coating that acts as a physical barrier, preventing saltwater and moisture from reaching the underlying steel. This coating also provides cathodic protection: if scratched, the zinc corrodes preferentially, sacrificing itself to protect the steel—a critical feature in high-traffic marine areas where minor abrasions are inevitable. From offshore platforms and port infrastructure to seawalls and marine bridges, these tubes ensure structural integrity, reducing maintenance costs and extending the lifespan of marine projects.

The 20-year rust prevention guarantee is not merely a marketing claim but a testament to the tubes’ exceptional durability, backed by rigorous testing and real-world performance data. Accelerated corrosion tests, simulating decades of exposure to salt spray, humidity, and temperature fluctuations, confirm that the zinc coating retains its protective properties for at least 20 years. This longevity is a game-changer for outdoor and marine projects, where frequent maintenance or replacement of structural components is costly and disruptive. In coastal regions, for example, a seawall constructed with these tubes can operate maintenance-free for two decades, avoiding the need for regular repainting or part replacements that would otherwise disrupt coastal ecosystems and local communities. For infrastructure managers and project owners, this guarantee translates to predictable long-term costs, reduced downtime, and enhanced safety—critical factors in large-scale outdoor and marine developments.

As the preferred choice for outdoor projects, these square tubes offer versatility that spans a wide range of applications beyond marine engineering. In civil engineering, they serve as structural supports for highway guardrails, outdoor pavilions, and transmission towers, withstanding rain, snow, and UV radiation. In landscaping, they provide frameworks for pergolas, fences, and outdoor lighting, maintaining their aesthetic appeal despite constant exposure to the elements. Agricultural projects, such as greenhouse frames and irrigation system supports, benefit from their resistance to fertilizers and pesticides, which can corrode lesser materials. The square shape of the tubes adds to their practicality: their flat surfaces simplify attachment of brackets, panels, and other components, reducing installation time and ensuring secure connections. Whether used in urban parks, rural farmlands, or coastal boardwalks, these tubes deliver consistent performance, making them a staple in outdoor construction.

The structural integrity of these hot-dip galvanized square tubes is another key advantage, derived from their high-quality steel core and precise manufacturing. The square cross-section provides superior load-bearing capacity compared to round tubes, distributing weight evenly across all four sides. This makes them ideal for supporting heavy loads in outdoor structures, such as roof trusses for open-air stadiums or canopies in public squares. The uniform wall thickness, ensured by strict quality control, guarantees consistent strength throughout the tube, eliminating weak points that could fail under stress. Engineers can rely on these tubes to meet or exceed industry standards for tensile strength and impact resistance, enabling the design of ambitious outdoor projects with confidence.

Aesthetic versatility further enhances their appeal in outdoor settings. The smooth, uniform zinc coating provides a clean, industrial look that complements modern architectural designs, from minimalist urban plazas to rugged coastal installations. For projects requiring a specific color scheme, the tubes can be painted or powder-coated without compromising their corrosion resistance, allowing seamless integration with surrounding structures. This adaptability ensures that functionality does not come at the expense of visual harmony, making them a favorite among architects and designers working on high-visibility outdoor projects.

The environmental benefits of these tubes extend to their role in climate resilience. As extreme weather events become more frequent, outdoor infrastructure must withstand stronger storms, higher tides, and more intense sunlight. The 20-year rust prevention guarantee ensures that structures built with these tubes remain resilient over time, reducing the need for reconstruction and minimizing the carbon footprint associated with repeated construction cycles. In coastal areas threatened by rising sea levels, marine engineering projects using these tubes contribute to sustainable coastal protection, balancing human needs with ecosystem preservation.

In summary, environmental-friendly hot-dip galvanized square tubes represent a paradigm shift in construction materials, merging sustainability with uncompromising performance. Their eco-conscious manufacturing, ability to thrive in marine environments, 20-year rust prevention guarantee, and versatility in outdoor projects make them an indispensable choice for modern construction. Whether safeguarding coastal communities, enhancing urban landscapes, or supporting agricultural innovation, these tubes deliver durability, sustainability, and peace of mind—proving that environmental responsibility and engineering excellence can go hand in hand. For project managers, engineers, and architects seeking materials that stand the test of time and tides, these hot-dip galvanized square tubes are the clear preferred choice.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.