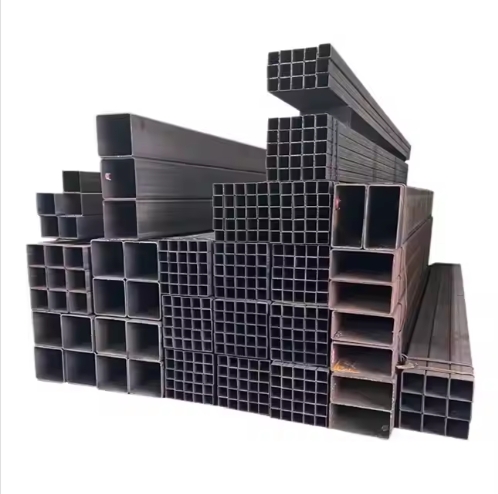

Hot-dip galvanized square pipes for scaffolding, 50x50x2.5mm, Q235B, national standard, with strong load-bearing capacity

Category:

Summary description:

Keywords:

Details

Hot-dip galvanized square pipes tailored for scaffolding, featuring the specification of 50x50x2.5mm, crafted from Q235B steel, adhering to national standards, and boasting strong load-bearing capacity, are indispensable components in construction and industrial scaffolding systems. These pipes are engineered to deliver exceptional performance, safety, and durability, meeting the rigorous demands of temporary elevated structures used in building, maintenance, and renovation projects.

At the heart of these scaffolding pipes is Q235B steel, a high-quality carbon structural steel renowned for its superior mechanical properties. Q235B offers an excellent combination of tensile strength and yield strength, which are crucial for withstanding the heavy loads and dynamic stresses that scaffolding systems encounter. This steel grade provides the necessary rigidity to support the weight of workers, tools, construction materials, and even temporary equipment like concrete mixers or welding machines. Unlike lower-grade steels that may deform under pressure, Q235B maintains its structural integrity, ensuring the scaffolding remains stable and secure throughout the project duration. Additionally, Q235B steel exhibits good weldability and formability, allowing for easy fabrication of connections, such as couplers and brackets, which are essential for assembling the scaffolding framework into a cohesive and robust structure.

The 50x50x2.5mm dimension is a carefully selected 规格 (specification) that optimizes the balance between weight and load-bearing capability for scaffolding applications. The 50mm x 50mm square cross-section provides a large and stable base, distributing the applied loads evenly across the structure. This square shape offers more contact area compared to round pipes, enhancing the stability of the scaffolding when connected to other components like horizontal ledgers, vertical standards, and diagonal braces. The 2.5mm wall thickness is a critical factor in ensuring the pipes can withstand heavy loads without buckling or bending. This thickness strikes a perfect balance—thick enough to provide the required strength yet not overly heavy, making the pipes manageable during transportation, handling, and installation. It also ensures that the pipes have sufficient resistance to impact, which is important in busy construction sites where accidental collisions with equipment or materials are common.

Adherence to national standards is a defining characteristic that sets these scaffolding pipes apart. National standards for scaffolding materials specify strict requirements for dimensions, mechanical properties, galvanization quality, and load-bearing capacity. By complying with these standards, these 50x50x2.5mm Q235B pipes guarantee consistent quality and performance across every unit. This uniformity is vital for scaffolding systems, as any variation in the strength or dimensions of individual components could compromise the overall stability of the structure. Compliance with national standards also ensures that the pipes meet safety regulations, providing peace of mind to contractors, workers, and project managers that the scaffolding is built to withstand the intended loads and environmental conditions. It also facilitates easier inspection and certification of the scaffolding system, as inspectors can rely on the pipes meeting established benchmarks.

The strong load-bearing capacity of these hot-dip galvanized square pipes is a key advantage in scaffolding applications. Scaffolding systems must support not only static loads, such as stacked building materials, but also dynamic loads from workers moving around, tools being transported, and even environmental factors like wind pressure. The 50x50x2.5mm Q235B pipes are designed to handle these diverse loads, with their robust construction and high-strength steel ensuring that the scaffolding remains stable and secure. This load-bearing capability allows for the construction of multi-level scaffolding structures, which are often necessary for high-rise building projects or large-scale industrial maintenance work. It also provides flexibility in the design of the scaffolding, enabling it to be adapted to different project requirements, whether it's a simple single-level platform or a complex system with multiple working decks.

The hot-dip galvanizing treatment applied to these square pipes enhances their durability and longevity, even in harsh construction environments. Scaffolding systems are typically exposed to a wide range of weather conditions, including rain, snow, humidity, and extreme temperatures, as well as contact with construction materials like concrete, mortar, and chemicals. The hot-dip galvanizing process involves immersing the Q235B steel pipes in a bath of molten zinc, forming a thick, uniform, and tightly bonded zinc coating on the surface. This coating acts as a powerful barrier against corrosion, rust, and degradation, preventing the steel from being damaged by moisture and other corrosive elements. Unlike painted or powder-coated pipes, which can chip or wear away over time, the galvanized layer is metallurgically bonded to the steel, ensuring long-term protection. This resistance to corrosion significantly extends the service life of the scaffolding pipes, reducing the need for frequent replacements and lowering maintenance costs.

These 50x50x2.5mm hot-dip galvanized square pipes are highly versatile and find application in a wide range of scaffolding systems. They are suitable for use in construction scaffolding for building new structures, where they provide a safe and stable working platform at various heights. They are also ideal for maintenance and renovation projects, allowing workers to access hard-to-reach areas of existing buildings or industrial facilities. In addition, these pipes are used in temporary event structures, such as stages and grandstands, where their load-bearing capacity and durability are essential for ensuring the safety of attendees. Their square shape makes them easy to connect using standard scaffolding couplers and fittings, enabling quick and efficient assembly and disassembly of the scaffolding system, which is important for meeting tight project deadlines.

Installation of these scaffolding pipes is straightforward, thanks to their consistent dimensions and compatibility with standard scaffolding components. The 50x50mm square profile fits perfectly with common couplers, which are used to join vertical and horizontal pipes, as well as diagonal braces, creating a rigid and stable framework. The hot-dip galvanized surface is smooth, reducing friction during installation and making it easier to slide couplers into place. The 2.5mm wall thickness ensures that the pipes can be securely clamped without being damaged, maintaining the integrity of the connections. This ease of installation not only saves time and labor costs but also ensures that the scaffolding can be erected quickly, allowing construction work to proceed without unnecessary delays.

In summary, hot-dip galvanized square pipes for scaffolding (50x50x2.5mm, Q235B, national standard, with strong load-bearing capacity) are essential components for safe and reliable scaffolding systems. Their Q235B steel construction provides the necessary strength, the 50x50x2.5mm offers optimal stability and manageability, compliance with national standards ensures quality and safety, and the hot-dip galvanized coating guarantees durability in harsh environments. Whether used in construction, maintenance, or event setups, these pipes deliver the performance and reliability needed to support workers and materials at height, contributing to the success and safety of various projects.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.