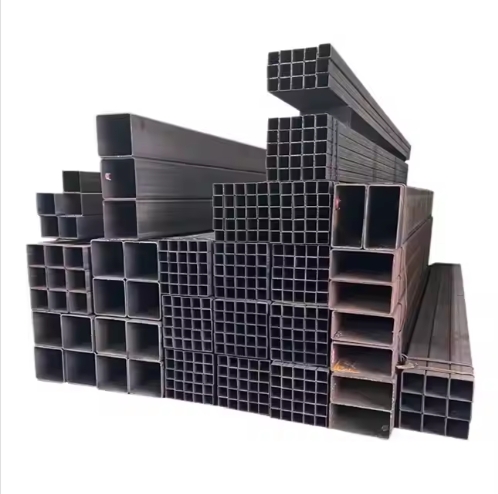

Hot-dip galvanized square pipes for greenhouse frames, 25x25x1.2mm, Q195, 6-meter fixed length, corrosion-resistant.

Category:

Summary description:

Keywords:

Details

Hot-dip galvanized square pipes designed specifically for greenhouse frames, with the specification of 25x25x1.2mm, crafted from Q195 steel, and available in 6-meter fixed lengths, stand as a specialized solution tailored to the unique demands of agricultural and horticultural structures. These pipes combine corrosion resistance, structural efficiency, and practical design to ensure the stability and longevity of greenhouse frameworks, even in the challenging environments they operate within.

At the core of these pipes is Q195 steel, a low-carbon steel known for its balanced combination of ductility and strength—properties that are particularly valuable for greenhouse construction. Q195 offers sufficient tensile strength to support the weight of greenhouse coverings, such as polycarbonate panels or polyethylene films, while its malleability allows for easy bending and shaping into the curved or angled sections often required in greenhouse designs. This flexibility in fabrication enables the creation of customized frame structures, from simple hoop houses to more complex multi-span greenhouses, without compromising the material’s integrity. Unlike higher-carbon steels that may be brittle when bent, Q195 retains its structural cohesion, ensuring the frame can withstand the stresses of installation and ongoing use.

The 25x25x1.2mm dimension is a carefully optimized (specification) for greenhouse frames, striking a perfect balance between weight and strength. The 25mm x 25mm square cross-section provides ample stability for vertical supports, horizontal beams, and roof trusses, distributing the load of the structure evenly across the frame. This compact size prevents excessive material usage, keeping the overall weight of the greenhouse low—an important factor for both cost efficiency and ease of installation, especially in temporary or semi-permanent setups. The 1.2mm wall thickness, while lightweight, offers sufficient resistance to deformation from wind pressure, snow accumulation, or the weight of hanging plants or irrigation systems. This thickness ensures the pipes remain rigid enough to maintain the greenhouse’s shape yet thin enough to minimize material waste, aligning with the economic needs of agricultural operations.

A defining feature of these pipes is their hot-dip galvanized coating, which delivers exceptional corrosion resistance—a critical attribute for greenhouse environments. Greenhouses are inherently humid spaces, with constant condensation, irrigation runoff, and exposure to fertilizers or pesticides that can accelerate metal corrosion. The hot-dip galvanizing process involves immersing the Q195 steel pipes in molten zinc, forming a metallurgically bonded protective layer that seals the steel from moisture and chemical exposure. This coating acts as a sacrificial barrier, meaning it corrodes slowly over time to protect the underlying steel, significantly extending the pipe’s service life. Unlike painted or powder-coated alternatives that may chip or peel in humid conditions, the galvanized layer remains intact, ensuring long-term protection against rust and degradation.

The 6-meter fixed length of these pipes enhances their practicality for greenhouse construction. This standard length aligns with the modular designs common in greenhouse frameworks, allowing for efficient assembly with minimal cutting or waste. For example, 6-meter sections can be easily joined to form longer spans for roof supports or cut to size for vertical posts, reducing on-site labor and material loss. The fixed length also simplifies transportation and storage, as pipes can be stacked uniformly, minimizing logistics challenges for agricultural operations—whether they are small family farms or large commercial horticultural facilities. This standardization streamlines the construction process, enabling faster setup of greenhouses and reducing project timelines.

Corrosion resistance is perhaps the most vital property of these pipes in the context of greenhouse use. The humid interior environment, combined with occasional exposure to rain, snow, or soil moisture from the exterior, creates ideal conditions for metal degradation. The hot-dip galvanized coating ensures that the pipes resist rust even after years of continuous use, maintaining their structural integrity and avoiding the costly and disruptive need for frequent replacements. This durability is particularly valuable for greenhouse frames, which are often difficult to access for repairs once the structure is enclosed with coverings. A corrosion-resistant frame also prevents contamination risks—rust particles that could otherwise mix with soil or irrigation water are eliminated, safeguarding plant health.

Beyond their structural role, these pipes contribute to the overall efficiency of greenhouse operations. Their lightweight design reduces the load on foundation systems, allowing for simpler and more cost-effective base constructions, such as concrete footings or ground anchors. The smooth surface of the galvanized coating minimizes friction with greenhouse coverings, preventing tears or abrasions in materials like polyethylene film. Additionally, the square shape of the pipes provides flat surfaces for secure attachment of brackets, clips, or irrigation components, enabling easy integration of auxiliary systems such as ventilation fans, shading devices, or drip irrigation lines.

These 25x25x1.2mm pipes are versatile enough to accommodate various greenhouse types. They are ideal for small to medium-sized structures, such as backyard greenhouses for hobby gardeners, as well as larger commercial operations growing vegetables, flowers, or seedlings. In high-tunnel greenhouses, their lightweight yet sturdy nature helps withstand wind loads without requiring excessive bracing. In multi-span greenhouses, their uniform dimensions ensure consistent structural performance across the entire frame, reducing the risk of uneven stress points that could lead to collapse.

Installation of these pipes is straightforward, thanks to their compatibility with standard hardware and joining methods. They can be easily connected using bolts, screws, or welding, allowing for flexible assembly based on the greenhouse design. The 6-meter length simplifies the creation of continuous roof trusses or side walls, while the 25mm square profile fits standard brackets and connectors commonly used in agricultural construction. This ease of installation is particularly beneficial for farmers or growers who may not have access to specialized construction equipment, enabling them to assemble or expand their greenhouses with minimal external support.

In summary, hot-dip galvanized square pipes for greenhouse frames (25x25x1.2mm, Q195, 6-meter fixed length) represent a purpose-built solution for agricultural structures. Their Q195 steel core offers the right balance of strength and flexibility, the 25x25x1.2mm optimizes weight and stability, the hot-dip galvanized coating ensures corrosion resistance in humid environments, and the 6-meter fixed length enhances practicality. Whether used in small-scale gardens or large commercial operations, these pipes provide a durable, cost-effective, and reliable framework that supports healthy plant growth while minimizing maintenance and replacement costs—ultimately contributing to the efficiency and success of horticultural endeavors.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.