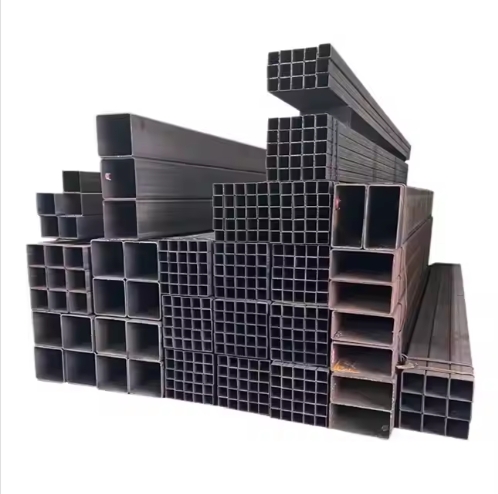

Q235B hot-dip galvanized spiral steel pipe, Φ219*6mm, national standard GB/T 3091, spiral welded pipe, 6 meters per piece.

Category:

Summary description:

Keywords:

Details

Q235B hot-dip galvanized spiral steel pipe, Φ219*6mm, adhering to the national standard GB/T 3091, is a high-quality spiral welded pipe with a length of 6 meters per piece, which has won wide recognition in various industrial fields. This pipe combines excellent material properties, advanced manufacturing technology and strict quality standards, making it an ideal choice for fluid transportation, structural support and other applications.

The Q235B grade is a key factor in determining the performance of this spiral steel pipe. Q235B is a common carbon structural steel with a minimum yield strength of 235 MPa, which has good plasticity and toughness. This kind of steel is easy to process and weld, and can be flexibly adapted to various installation environments and construction requirements. Whether it is cutting, bending or connecting, Q235B steel can maintain stable performance, ensuring the reliability and safety of the pipe in the application process. In addition, the carbon content of Q235B steel is moderate, which makes the pipe have a good balance between strength and ductility, and can withstand certain pressure and external impact.

The hot-dip galvanizing process is another important feature that makes this spiral steel pipe stand out. In the hot-dip galvanizing process, the spiral steel pipe is immersed in a molten zinc bath, so that a uniform and dense zinc layer is formed on the surface of the pipe. This zinc layer can effectively isolate the steel from the external environment, preventing oxygen, water and other corrosive substances from contacting the steel matrix, thus achieving excellent anti-corrosion and anti-rust effects. Compared with other anti-corrosion methods, hot-dip galvanizing has the advantages of long service life, strong adhesion and uniform coating. Even in harsh environments such as humidity, salinity and acid-base, the hot-dip galvanized layer can still maintain good performance, greatly extending the service life of the pipe.

The specification of Φ219*6mm makes this spiral steel pipe have unique application value. The outer diameter of 219mm ensures that the pipe has a certain flow capacity, which is suitable for medium and small-scale fluid transportation projects, such as urban water supply and drainage, industrial circulating water systems, and agricultural irrigation. The wall thickness of 6mm gives the pipe sufficient structural strength to withstand the pressure during fluid transportation and the external load during installation and use. At the same time, this thickness also makes the pipe have a moderate weight, which is convenient for transportation, loading and unloading and on-site construction, reducing the difficulty and cost of construction.

Adhering to the national standard GB/T 3091 is a strong guarantee for the quality of this spiral steel pipe. GB/T 3091 is a national standard in China that specifies the requirements for welded steel pipes for low-pressure fluid transportation. This standard covers various aspects such as the material, dimensions, mechanical properties, welding quality, galvanizing layer thickness and testing methods of the pipes. By complying with GB/T 3091, the Q235B hot-dip galvanized spiral steel pipe ensures that it meets strict quality standards in every production link. For example, in terms of dimensional accuracy, the pipe's outer diameter, wall thickness and length all meet the specified tolerances, ensuring the consistency and interchangeability of the product. In terms of performance testing, the pipe has passed hydrostatic testing, flattening testing and other tests to ensure that it does not leak and has sufficient strength under working pressure.

The spiral welded structure is another prominent advantage of this pipe. The spiral welding process is to roll the steel strip into a spiral shape and weld the edges continuously. This welding method makes the stress distribution of the pipe more uniform, and the bearing capacity is stronger than that of straight seam welded pipes. The spiral weld has a longer length, which can disperse the stress generated by internal pressure and external force, reducing the risk of weld cracking. In addition, the spiral welding process can produce pipes of different lengths and specifications according to the needs of customers, and the 6-meter length per piece is a commonly used specification in engineering, which can reduce the number of joints in the pipeline system, improve the efficiency of installation and reduce the possibility of leakage.

The 6-meter length per piece of this spiral steel pipe brings many conveniences to engineering construction. In the process of transportation, 6-meter pipes are easy to load and unload, and can make full use of the space of transport vehicles, reducing transportation costs. In the installation process, the 6-meter length can reduce the number of connections between pipes, shorten the construction time and improve the construction efficiency. At the same time, fewer joints also mean less risk of leakage, which is very important for ensuring the tightness and safety of the pipeline system. For projects with special length requirements, the 6-meter pipes can also be cut and connected as needed to meet the specific needs of the project.

The application range of Q235B hot-dip galvanized spiral steel pipe is very wide. In the field of municipal engineering, it is often used in urban water supply pipelines, drainage pipelines and sewage treatment pipelines. The hot-dip galvanizing layer can effectively resist the corrosion of various substances in the water and soil, ensuring the long-term operation of the municipal pipeline system. In industrial production, this pipe is suitable for transporting industrial cooling water, chemical liquids (non-strong corrosive) and other media, and its good welding performance and pressure resistance can meet the needs of industrial production. In agricultural production, it can be used as an irrigation pipeline to transport water resources to farmland, improving irrigation efficiency and ensuring crop growth. In addition, it can also be used in construction engineering as a structural support pipe, such as the support of scaffolding and the pipeline of fire protection systems.

In terms of installation and maintenance, Q235B hot-dip galvanized spiral steel pipe has obvious advantages. Due to its good weldability, it can be connected by welding, flange connection and other methods, and the connection is firm and reliable. During installation, as long as the corresponding construction specifications are followed, the tightness and stability of the pipeline can be guaranteed. In terms of maintenance, because of the protection of the hot-dip galvanizing layer, the pipe is not easy to rust and corrode, and the maintenance workload is small. Regular inspection and cleaning can ensure the long-term normal operation of the pipeline. Even if local damage occurs, it can be repaired by simple methods such as patching and re-galvanizing, reducing maintenance costs and extending the service life of the pipeline.

From the perspective of economy and durability, Q235B hot-dip galvanized spiral steel pipe has high cost performance. Compared with some high-alloy steel pipes, the price of Q235B steel pipe is more reasonable, which can reduce the initial investment of the project. At the same time, due to its good anti-corrosion performance and long service life, the replacement frequency of the pipe is reduced, and the long-term operation cost is saved. The 6-meter length per piece also reduces the number of accessories and installation man-hours, further reducing the overall cost of the project. For projects with limited budgets but high requirements for quality and service life, this pipe is a very cost-effective choice.

In terms of environmental protection, Q235B hot-dip galvanized spiral steel pipe also has certain advantages. The hot-dip galvanizing process uses zinc, which is a relatively environmentally friendly metal. The galvanizing layer can be recycled, reducing the waste of resources. In addition, the long service life of the pipe reduces the consumption of raw materials and energy caused by frequent replacement, which is in line with the concept of sustainable development. After the pipe is scrapped, the steel can be recycled and reused, reducing environmental pollution.

In conclusion, Q235B hot-dip galvanized spiral steel pipe, Φ219*6mm, complying with national standard GB/T 3091, with 6 meters per piece, is a high-quality, reliable and cost-effective product. Its excellent material properties, advanced manufacturing technology, strict quality standards and wide application range make it play an important role in various engineering projects. Whether in municipal construction, industrial production or agricultural development, this spiral steel pipe can provide stable and efficient service, contributing to the construction and development of various undertakings.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.