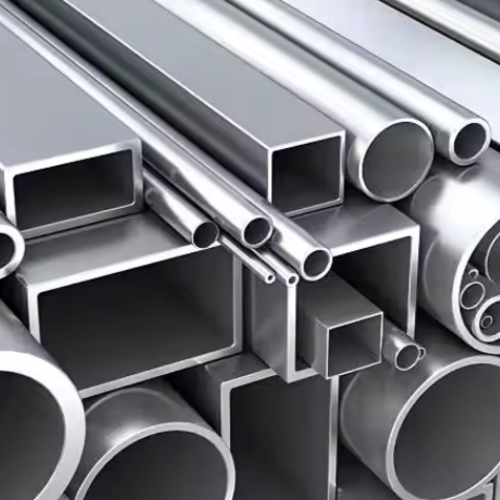

Hot-dip galvanized square steel pipes, made of Q345B material, weather-resistant and anti-rust, steel components for outdoor engineering

Category:

Summary description:

Keywords:

Details

Hot-dip galvanized square steel pipes, crafted from Q345B material, are a revolutionary solution for outdoor engineering projects, offering exceptional weather resistance and rust prevention capabilities. These steel components have become the cornerstone of countless outdoor structures, ensuring durability and reliability even in the harshest of environmental conditions.

Q345B is a high-quality low-alloy high-strength structural steel, renowned for its superior mechanical properties. With a minimum yield strength of 345 MPa, it far surpasses many conventional steel grades, enabling it to bear heavy loads and resist deformation effectively. The addition of alloying elements such as manganese, silicon, and vanadium enhances its strength, toughness, and weldability. This makes Q345B square steel pipes not only robust enough to withstand the mechanical stresses of construction but also adaptable to various fabrication techniques. Whether it's intricate welding for complex structural designs or precise cutting for custom installations, Q345B material maintains its integrity throughout the manufacturing process.

The hot-dip galvanization process is what truly elevates these square steel pipes to a new level of performance in outdoor environments. This process begins with meticulous pre-treatment of the pipes, involving degreasing to remove any surface contaminants, pickling to eliminate rust and scale, and fluxing to prepare the surface for galvanization. Once prepped, the pipes are submerged into a molten zinc bath at high temperatures. Through a metallurgical reaction, a series of zinc-iron alloy layers form on the steel surface, topped by a thick, continuous layer of pure zinc. This multi-layered zinc coating acts as a formidable barrier against the elements.

The zinc-iron alloy layers, being extremely hard and abrasion-resistant, protect the pipes from mechanical damage during transportation, installation, and the normal wear and tear of outdoor use. Meanwhile, the outer pure zinc layer serves as a sacrificial anode. In the presence of moisture, oxygen, and other corrosive agents commonly found in outdoor settings, zinc corrodes preferentially over steel. As the zinc gradually sacrifices itself, it continuously protects the underlying Q345B steel, effectively preventing rust formation and extending the lifespan of the pipes significantly. The result is a corrosion resistance that can endure decades, even in challenging environments like coastal areas with high salt content in the air, industrial zones with high levels of pollution, or regions with extreme temperature fluctuations.

In outdoor engineering, these hot-dip galvanized Q345B square steel pipes find extensive applications. In bridge construction, they are utilized as crucial components of the bridge's framework, providing the necessary strength to support heavy traffic loads while withstanding the constant exposure to wind, rain, and varying temperatures. Their weather resistance ensures that the bridge remains structurally sound over time, reducing the frequency and cost of maintenance. For large-scale outdoor advertising structures, such as billboards and signposts, the pipes offer both stability and durability. They can withstand strong winds and storms, safeguarding the advertising content and ensuring long-term visibility.

In the realm of infrastructure, these pipes are used for building outdoor walkways, platforms, and railings. Their combination of strength and rust prevention makes them ideal for public spaces, where safety and aesthetics are of paramount importance. The corrosion resistance of the hot-dip galvanized coating ensures that the structures retain their visual appeal, avoiding the unsightly rust stains that can mar other materials. Additionally, in the energy sector, for the construction of wind turbine foundations and solar panel support structures, Q345B square steel pipes play a vital role. They can endure the harsh outdoor conditions and mechanical stresses associated with these applications, contributing to the long-term efficiency and reliability of renewable energy installations.

In conclusion, hot-dip galvanized square steel pipes made of Q345B material are an indispensable asset for outdoor engineering. Their high-strength Q345B base material, coupled with the superior corrosion protection provided by the hot-dip galvanization process, makes them a reliable choice for a wide range of outdoor projects. From large-scale infrastructure to smaller-scale public installations, these steel components offer the perfect balance of strength, durability, and weather resistance, ensuring that outdoor structures stand the test of time.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.