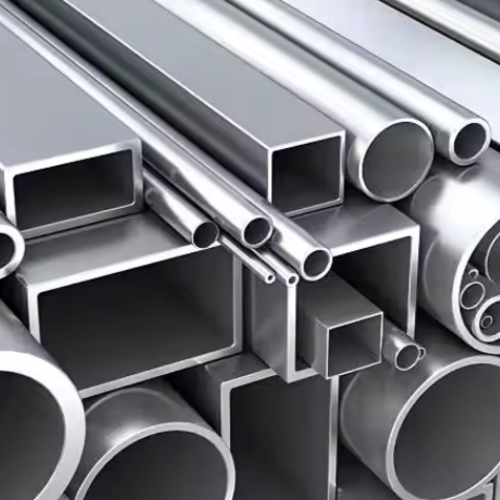

Hot-dip galvanized square pipes in accordance with GB/T 3094-2012, made of Q235B material, with sizes ranging from 20x20mm to 150x150mm, and zinc coating thickness ≥80μm

Category:

Summary description:

Keywords:

Details

Hot-dip galvanized square pipes produced in strict accordance with GB/T 3094-2012, crafted from Q235B material and available in sizes ranging from 20x20mm to 150x150mm with a zinc coating thickness of at least 80μm, are a remarkable testament to modern engineering and manufacturing excellence. These square pipes have become a cornerstone in a wide array of construction, industrial, and architectural applications, thanks to their unique combination of strength, durability, and corrosion resistance.

GB/T 3094-2012 is a comprehensive national standard that sets stringent requirements for the production of cold-formed welded square and rectangular steel tubes. This standard meticulously covers every aspect of the manufacturing process, from raw material procurement to final product inspection. It mandates that only high-quality materials, such as Q235B steel, should be used. Q235B, a common carbon structural steel, is renowned for its balanced mechanical properties. It offers adequate strength, with a yield strength of approximately 235 MPa, making it suitable for a variety of load-bearing applications. Additionally, it has good plasticity and weldability, which are crucial during the manufacturing process of square pipes. Manufacturers must adhere to strict procedures during production, including precise cutting, forming, and welding techniques, all of which are designed to ensure the dimensional accuracy, structural integrity, and surface quality of the pipes. Rigorous quality control measures, such as non-destructive testing and dimensional checks, are carried out at multiple stages to guarantee that each square pipe meets the exacting standards of GB/T 3094-2012.

The diverse size range of these square pipes, from the compact 20x20mm to the more substantial 150x150mm, offers unparalleled versatility. The smaller-sized pipes, like the 20x20mm ones, are ideal for applications that require lightweight yet sturdy structures, such as interior decoration frameworks, furniture manufacturing, and small-scale mechanical components. Their small cross-section allows for easy handling and installation in confined spaces. On the other hand, the larger 150x150mm square pipes are well-suited for heavy-duty construction projects. They can be used as columns, beams, and braces in industrial buildings, bridges, and large commercial structures, providing excellent load-bearing capacity and stability. The intermediate sizes in between offer a flexible range of options for projects with specific structural requirements, enabling engineers and architects to select the most appropriate pipe size to optimize structural performance while controlling costs.

The hot-dip galvanization process, which results in a zinc coating thickness of at least 80μm, is the key to the pipes' exceptional corrosion resistance. The process begins with thorough pre-treatment of the square pipes. This involves degreasing to remove any oil or grease residues, pickling to eliminate surface oxides, and fluxing to prepare the surface for galvanization. Once pre-treated, the pipes are immersed in a molten zinc bath at high temperatures. The heat triggers a chemical reaction that forms a series of zinc-iron alloy layers on the surface of the steel, topped by a pure zinc outer layer. The 80μm-thick zinc coating provides multi-layered protection. The zinc-iron alloy layers are hard and abrasion-resistant, safeguarding the pipe from mechanical damage during handling and installation. The outer pure zinc layer acts as a sacrificial anode. In the presence of moisture and oxygen, zinc corrodes preferentially over steel, gradually sacrificing itself to protect the underlying Q235B material. This makes the hot-dip galvanized square pipes highly resistant to rust and corrosion, even in harsh environments with high humidity, salt spray, or industrial pollutants. Compared to other anti-corrosion methods, such as painting or electroplating, hot-dip galvanization offers longer-lasting protection, often extending the service life of the pipes by decades.

In practical applications, these hot-dip galvanized square pipes shine in various fields. In the construction industry, they are used to build structural frameworks for buildings, providing a reliable and stable support system. Their corrosion resistance ensures that the structures remain intact over time, reducing maintenance costs. In the automotive and manufacturing sectors, they are employed in the fabrication of vehicle frames, equipment supports, and conveyor systems, where their strength and durability contribute to the overall performance and longevity of the products. For outdoor applications like fences, handrails, and signage supports, the pipes' ability to withstand the elements without deteriorating maintains the aesthetic and functional integrity of the installations.

In conclusion, hot-dip galvanized square pipes conforming to GB/T 3094-2012, made of Q235B material with a wide size range and a thick zinc coating, are a reliable and versatile solution for numerous engineering and construction needs. Their adherence to strict standards, combined with the inherent properties of the material and the effectiveness of the hot-dip galvanization process, makes them an essential choice for professionals seeking high-quality, long-lasting, and cost-efficient building materials.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.