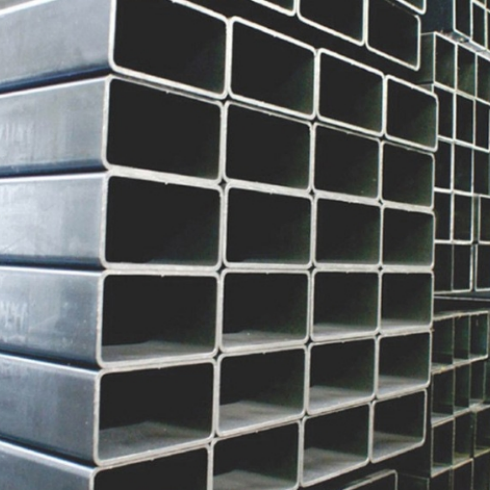

Large-diameter Q235 galvanized square tubes, hot-dip galvanized square and rectangular tubes in stock for glass curtain walls.

Category:

Summary description:

Keywords:

Details

Large-diameter Q235 galvanized square tubes, along with hot-dip galvanized square and rectangular tubes available in stock, stand as indispensable components in the construction of modern glass curtain walls, combining robust structural performance with exceptional durability. These specialized steel products have redefined industry standards for curtain wall frameworks, offering engineers and architects a reliable solution that balances strength, corrosion resistance, and aesthetic versatility. As glass curtain walls continue to dominate contemporary building designs—from sleek skyscrapers to innovative commercial complexes—these tubes provide the structural backbone needed to support large glass panels while withstanding the harshest environmental conditions.

At the core of their functionality is the Q235 steel grade, a widely acclaimed low-carbon structural steel known for its optimal balance of tensile strength and ductility. This material composition makes the large-diameter square tubes particularly suited for load-bearing applications in glass curtain walls, where they must support the weight of heavy glass panels, resist wind loads, and maintain structural integrity over decades. The "large-diameter" specification is a critical feature here, as it enables the tubes to distribute weight evenly across the curtain wall system, reducing stress on individual components and enhancing overall stability. Whether used in high-rise buildings exposed to strong winds or low-rise structures requiring expansive glass surfaces, these tubes provide the rigidity necessary to prevent deflection and ensure the curtain wall remains structurally sound.

The hot-dip galvanization process further elevates the performance of these square and rectangular tubes, making them a superior choice for glass curtain walls. Unlike other coating methods, hot-dip galvanization involves immersing the steel tubes in a molten zinc bath, creating a metallurgical bond between the zinc and the base steel. This results in a thick, uniform coating that offers unparalleled corrosion resistance—a vital attribute for curtain walls, which are constantly exposed to rain, humidity, UV radiation, and airborne pollutants. The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rust and degradation even if the surface is scratched or damaged. This longevity is especially valuable for glass curtain walls, which are designed to last the lifetime of the building; by choosing hot-dip galvanized tubes, project managers can significantly reduce maintenance costs and avoid the need for premature replacements.

In addition to their protective properties, hot-dip galvanized square and rectangular tubes offer aesthetic benefits that complement the transparency of glass curtain walls. The smooth, consistent finish of the zinc coating creates a clean, modern look that pairs seamlessly with glass, aluminum, and other contemporary building materials. Architects appreciate the versatility of these tubes, as they can be left exposed to enhance the industrial-chic aesthetic of a design or painted to match specific color schemes. This flexibility allows for greater creative freedom, enabling the creation of unique curtain wall designs that stand out while maintaining structural functionality.

The availability of these tubes in stock is a game-changer for construction projects, where tight deadlines and unexpected delays are common. Having hot-dip galvanized square and rectangular tubes readily available eliminates the long lead times associated with custom manufacturing, allowing contractors to procure materials quickly and keep projects on schedule. This is particularly advantageous for glass curtain wall installations, which often occur in the later stages of construction and must align with other finishing works. The in-stock inventory includes a range of dimensions, from large-diameter square tubes for main structural frameworks to smaller rectangular tubes for secondary supports, ensuring that every component of the curtain wall system can be sourced without delay.

Beyond their structural and logistical benefits, these tubes are engineered to meet the specific demands of glass curtain wall systems. Rectangular tubes, for example, are often used for horizontal supports, where their flat surfaces provide stable mounting points for glass panels and fastening systems. Square tubes, on the other hand, excel in vertical applications, offering equal strength in all directions to resist torsional forces caused by wind or seismic activity. The combination of square and rectangular profiles allows engineers to design curtain wall systems that are both efficient and cost-effective, tailoring the choice of tube to the specific load requirements of each section.

Quality assurance is a cornerstone of these large-diameter Q235 galvanized tubes, with rigorous testing protocols ensuring they meet industry standards for glass curtain wall applications. Each tube undergoes dimensional checks to verify consistency in diameter, wall thickness, and straightness—critical factors for ensuring proper fit and alignment during installation. Additionally, the galvanized coating is inspected for uniformity and thickness, with tests such as adhesion checks and corrosion resistance trials confirming its effectiveness. These quality control measures provide peace of mind to project stakeholders, ensuring that the tubes will perform as expected in real-world conditions.

The practical advantages of using these in-stock tubes extend to the installation process itself. Glass curtain wall assembly requires precise measurements and tight tolerances, and the consistent dimensions of the hot-dip galvanized tubes simplify on-site fabrication and fitting. Contractors can rely on the tubes to align perfectly with brackets, connectors, and glass panels, reducing the need for on-site modifications and minimizing installation time. This efficiency is especially valuable in urban construction projects, where time constraints and limited workspace can complicate installation logistics.

Environmental considerations also play a role in the appeal of these galvanized tubes. Hot-dip galvanization is a sustainable process that produces minimal waste, and the long lifespan of the tubes reduces the need for frequent material replacement—aligning with green building initiatives. Many modern glass curtain walls are designed to meet energy efficiency standards, and the durability of galvanized steel supports contributes to the overall sustainability of the building by reducing the carbon footprint associated with maintenance and repairs. Additionally, zinc is a fully recyclable material, making these tubes an eco-friendly choice for projects aiming to achieve LEED or other green building certifications.

In conclusion, large-diameter Q235 galvanized square tubes and hot-dip galvanized square and rectangular tubes in stock represent a perfect synergy of strength, durability, and practicality for glass curtain wall construction. Their Q235 steel composition ensures structural integrity, while hot-dip galvanization provides long-lasting corrosion resistance—critical for withstanding environmental exposure. The availability of these tubes in stock streamlines project timelines, while their versatile profiles and aesthetic appeal empower architects to realize innovative designs. Whether used in towering skyscrapers or contemporary commercial buildings, these galvanized tubes deliver the performance, reliability, and value needed to create glass curtain walls that are both visually striking and built to last. For construction professionals seeking a superior framework solution, these tubes stand as the gold standard in the industry.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.