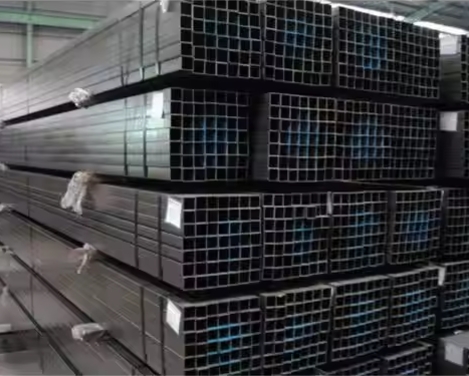

Hot-dip galvanized square tubes with multiple specifications available: 30*30, 40*40, 50*50, thickness 1.5-3.0mm, 6 meters per piece, for wholesale.

Category:

Summary description:

Keywords:

Details

High-quality carbon steel hot-dip galvanized square tubes in the 80x80x3.0mm specification stand as a testament to engineering excellence, designed to meet the rigorous demands of large-scale steel structures. With their thick zinc coating and exceptional weather resistance, these tubes offer a winning combination of strength, durability, and longevity, making them an indispensable choice for projects where structural integrity and reliability are non-negotiable. Whether used in industrial facilities, commercial complexes, or infrastructure developments, these square tubes deliver consistent performance even in the harshest environmental conditions, ensuring that large-scale structures remain stable and secure for decades to come.

At the core of these square tubes is the use of high-quality carbon steel, a material renowned for its exceptional mechanical properties. Carbon steel, with its optimal carbon content, strikes a perfect balance between tensile strength and ductility, allowing the tubes to withstand heavy loads without succumbing to deformation or failure. This makes them particularly well-suited for large-scale steel structures, where the ability to bear significant weight—from the structure itself to external forces like wind, snow, and seismic activity—is critical. The high-quality nature of the carbon steel ensures uniformity in composition and performance across all tubes, eliminating weak points that could compromise the overall structure. This consistency is further enhanced by stringent manufacturing processes, which include precise rolling and forming to achieve the 80x80x3.0mm dimensions with minimal tolerances.

The 80x80x3.0mm specification is carefully engineered to meet the specific needs of large-scale steel structures. The 80mm x 80mm square cross-section provides a large surface area for load distribution, ensuring that weight is spread evenly across the structure to minimize stress on individual components. This design is particularly advantageous in applications such as columns, beams, and trusses, where the square shape offers greater rigidity than round tubes, reducing deflection and enhancing overall stability. The 3.0mm wall thickness adds an extra layer of strength, making the tubes capable of withstanding the extreme forces encountered in large-scale projects. Unlike thinner-walled alternatives, these tubes offer the robustness needed to support multi-story buildings, large industrial plants, and sprawling infrastructure, ensuring that the structure remains intact even under peak loads.

A defining feature of these square tubes is their hot-dip galvanized coating, which plays a crucial role in enhancing their durability and weather resistance. The hot-dip galvanization process involves immersing the carbon steel tubes in a bath of molten zinc, creating a metallurgical bond that forms a protective layer over the entire surface of the tube—including corners, edges, and welds. This coating, which is significantly thicker than that achieved through other galvanization methods, acts as a barrier against moisture, oxygen, and corrosive substances, preventing rust and degradation. For large-scale steel structures, which are often exposed to the elements—rain, snow, humidity, and industrial pollutants—this corrosion resistance is invaluable. It ensures that the tubes maintain their structural integrity over time, reducing the need for costly maintenance and replacements and extending the lifespan of the entire structure.

The thick zinc coating on these square tubes is a key factor in their exceptional weather resistance. Unlike paint or other surface treatments that can chip, peel, or wear away, the thick zinc layer provides long-lasting protection, even in harsh environments. In coastal areas, where saltwater spray can accelerate corrosion, the thick zinc coating acts as a sacrificial barrier, corroding slowly to protect the underlying carbon steel. In industrial zones, where exposure to chemicals and pollutants is common, the coating resists degradation, ensuring that the tubes remain strong and functional. This weather resistance makes the tubes suitable for a wide range of outdoor applications, from bridges and stadiums to power plants and manufacturing facilities, where they are exposed to diverse and challenging conditions.

Designed specifically for large-scale steel structures, these hot-dip galvanized square tubes offer numerous advantages in terms of installation and integration. Their uniform 80x80x3.0mm dimensions ensure a perfect fit with other structural components, such as brackets, connectors, and fasteners, simplifying the assembly process. The square shape allows for easy alignment and bracing, reducing the time and labor required to construct complex frameworks. In large-scale projects, where time is of the essence, this ease of installation can significantly speed up construction timelines, helping to keep projects on schedule and within budget. Additionally, the tubes can be easily cut, welded, or drilled to meet specific design requirements, providing flexibility in customization without compromising their structural integrity.

Another key advantage of these high-quality carbon steel square tubes is their cost-effectiveness over the long term. While the initial investment in hot-dip galvanized tubes may be higher than that of uncoated or painted alternatives, their extended lifespan and reduced maintenance needs result in lower overall costs over the life of the structure. Large-scale steel structures, such as industrial plants or commercial buildings, have long service lives—often 50 years or more—and the durability of these tubes ensures that they do not need to be replaced during this period. This eliminates the need for frequent repairs, which can be disruptive and expensive in large-scale projects, and reduces the total cost of ownership significantly. For project managers and developers, this long-term cost savings makes the tubes a wise investment, even with their higher upfront price.

The versatility of these 80x80x3.0mm hot-dip galvanized square tubes is evident in their wide range of applications in large-scale steel structures. In industrial settings, they are used to construct the frameworks of factories, warehouses, and manufacturing plants, providing the strength needed to support heavy machinery, overhead cranes, and storage systems. In commercial construction, they form the backbone of shopping malls, office towers, and exhibition centers, where their durability ensures the safety of occupants and the longevity of the building. In infrastructure projects, they are employed in bridges, airports, and railway stations, where they withstand constant use and exposure to the elements. The tubes also play a crucial role in renewable energy projects, such as solar farms and wind turbine structures, where their weather resistance ensures reliable performance in remote and often harsh locations.

Quality control is a top priority in the manufacturing of these high-quality carbon steel square tubes, ensuring that each unit meets the highest standards of performance and reliability. Manufacturers subject the tubes to rigorous testing throughout the production process, from the selection of raw materials to the final inspection of the galvanized coating. Tensile strength tests, impact tests, and corrosion resistance tests are conducted to verify that the tubes can withstand the demands of large-scale steel structures. Dimensional checks ensure that the 80x80x3.0mm 规格 is consistent across all tubes, eliminating variations that could affect the integrity of the structure. These quality assurance measures provide engineers, contractors, and project managers with the confidence that the tubes will perform as expected, even in the most challenging conditions.

Environmental sustainability is another important benefit of these hot-dip galvanized square tubes. Carbon steel is one of the most recycled materials in the world, and these tubes are fully recyclable at the end of their service life, reducing waste and conserving natural resources. The hot-dip galvanization process uses zinc, a naturally occurring and 100% recyclable element, and modern galvanizing facilities operate in compliance with strict environmental regulations to minimize emissions and waste. By choosing these tubes for large-scale steel structures, project developers can align with sustainable construction practices, reducing the environmental impact of their projects and contributing to global efforts to combat climate change. This makes the tubes not only a practical choice but also an environmentally responsible one.

In conclusion, high-quality carbon steel hot-dip galvanized square tubes in the 80x80x3.0mm specification are an exceptional choice for large-scale steel structures. Their combination of high-quality carbon steel, thick zinc coating, and robust dimensions ensures strength, durability, and weather resistance, making them capable of withstanding the demands of even the most challenging projects. Whether used in industrial facilities, commercial buildings, or infrastructure developments, these tubes provide the structural integrity needed to keep large-scale structures stable and secure for decades. With their ease of installation, cost-effectiveness over time, and environmental sustainability, they represent a smart investment for any project seeking reliable and long-lasting structural solutions. For engineers, contractors, and developers involved in large-scale steel construction, these hot-dip galvanized square tubes are an indispensable component that delivers performance, value, and peace of mind.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.