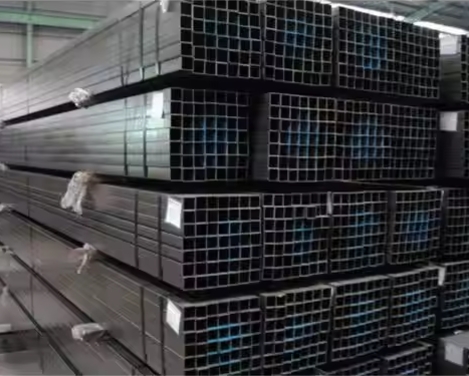

ASTM A500 GrB hot-dip galvanized square tubes, 2x2 inches x 14 Gauge (50x50x2.0mm), American standard.

Category:

Summary description:

Keywords:

Details

ASTM A500 GrB hot-dip galvanized square tubes, specifically the 2x2 inches x 14 Gauge (50x50x2.0mm) variant, represent the pinnacle of precision and performance in the realm of structural steel components. Manufactured to meet rigorous American standards, these tubes combine the strength of ASTM A500 Grade B steel with the protective benefits of hot-dip galvanization, resulting in a product that excels in durability, corrosion resistance, and versatility. Whether used in construction frameworks, industrial machinery, or architectural projects, these square tubes are designed to deliver consistent performance under demanding conditions, making them a trusted choice for engineers, contractors, and manufacturers across industries.

At the core of these tubes is their adherence to the ASTM A500 standard, a specification developed by the American Society for Testing and Materials (ASTM) that governs the production of cold-formed welded and seamless carbon steel structural tubing. Grade B (GrB) within this standard is particularly valued for its mechanical properties, including a minimum yield strength of 35,000 psi (241 MPa) and a tensile strength ranging from 58,000 to 79,000 psi (400 to 545 MPa). These properties ensure that the tubes can withstand significant loads, making them ideal for structural applications where strength and stability are paramount. The cold-forming process used to create these tubes also enhances their dimensional accuracy and surface finish, ensuring a uniform cross-section that simplifies installation and integration with other components.

The 2x2 inches x 14 Gauge (50x50x2.0mm) specification is a testament to the precision engineering behind these tubes. The 2x2 inch (50x50mm) square cross-section offers a balanced combination of structural rigidity and space efficiency, making it suitable for applications where both strength and a compact footprint are required. The 14 Gauge (2.0mm) wall thickness strikes an optimal balance between weight and durability—thick enough to provide robust support yet lightweight enough to simplify handling and installation. This specification is particularly popular in projects where material efficiency is key, as it minimizes unnecessary weight without compromising on performance, reducing both transportation costs and the overall load on the structure.

Hot-dip galvanization is a critical feature that sets these square tubes apart, significantly enhancing their longevity and resistance to environmental damage. The process involves immersing the fabricated steel tubes in a bath of molten zinc, which bonds to the surface of the steel to form a protective coating. This coating, typically 85-120 microns thick, acts as a physical barrier against moisture, oxygen, and corrosive substances, preventing rust and degradation. Unlike paint or other surface treatments, which may crack or peel over time, the zinc coating in hot-dip galvanization forms a metallurgical bond with the steel, ensuring uniform coverage even in hard-to-reach areas such as corners and welds. This makes the tubes particularly well-suited for outdoor applications, coastal environments, or industrial settings where exposure to chemicals, salt, or humidity is common.

Compliance with American standards is another key advantage of these ASTM A500 GrB tubes, providing assurance to users that the product meets strict quality and performance criteria. The ASTM A500 standard includes requirements for chemical composition, mechanical properties, dimensional tolerances, and testing procedures, ensuring consistency across manufacturers and batches. For projects in the United States and other regions that recognize American standards, this compliance simplifies regulatory approvals and ensures compatibility with other components designed to meet the same standards. Engineers and contractors can rely on these tubes to perform as expected, reducing the risk of structural failures or performance issues that could arise from using non-compliant materials.

The 2x2 inches x 14 Gauge (50x50x2.0mm) size makes these hot-dip galvanized square tubes highly versatile, suitable for a wide range of applications across industries. In construction, they are frequently used as structural supports in light to medium-duty frameworks, such as wall studs, roof trusses, and floor joists. Their square shape provides greater stability than round tubes in these applications, as the flat surfaces distribute loads more evenly and allow for secure connections with screws, bolts, or welds. Additionally, their corrosion resistance makes them ideal for exterior structures like canopies, awnings, and fencing, where exposure to rain, snow, and UV radiation would quickly degrade uncoated steel.

Industrial applications also benefit greatly from these ASTM A500 GrB tubes. They are commonly used in the fabrication of machinery frames, conveyor systems, and storage racks, where their strength and durability ensure reliable performance in high-traffic or heavy-use environments. The 14 Gauge wall thickness provides sufficient resistance to impact and vibration, protecting sensitive equipment from damage. In manufacturing facilities, these tubes may also be used as part of material handling systems, such as carts or platforms, where their lightweight design simplifies maneuverability without sacrificing load-bearing capacity.

Architectural projects often leverage the aesthetic and functional properties of these square tubes. Their clean, uniform lines make them a popular choice for modern designs, such as railings, balustrades, and decorative trims. The hot-dip galvanized finish can be left exposed for a sleek, industrial look or painted to match specific color schemes, offering designers flexibility in achieving their vision. In addition to their visual appeal, these tubes provide the structural support needed for such features, ensuring safety and longevity in high-visibility areas like commercial buildings, public spaces, and residential complexes.

One of the standout benefits of these hot-dip galvanized square tubes is their long service life, which translates to cost savings over time. The zinc coating typically provides 30-50 years of corrosion protection in rural environments and 15-30 years in coastal or industrial areas, significantly outperforming uncoated steel or painted alternatives. This extended lifespan reduces the need for frequent replacements, lowering maintenance costs and minimizing downtime for repairs. For projects with long-term ownership horizons, such as public infrastructure or commercial buildings, this durability makes the tubes a cost-effective investment despite their slightly higher upfront cost compared to non-galvanized options.

Installation efficiency is another key advantage of these ASTM A500 GrB tubes. Their precise dimensions and consistent straightness ensure a tight fit with standard connectors, brackets, and fasteners, simplifying the assembly process. The square shape allows for easy alignment and bracing, reducing the time and labor required to complete installations. Whether welded, bolted, or screwed, these tubes maintain their structural integrity at joints, ensuring that the overall system remains strong and stable. This ease of installation is particularly valuable in time-sensitive projects, where meeting deadlines is critical to avoiding cost overruns.

Environmental sustainability is an increasingly important consideration in material selection, and these hot-dip galvanized square tubes excel in this area. Steel is one of the most recycled materials in the world, with a recycling rate of over 90% in North America, and ASTM A500 GrB tubes are fully recyclable at the end of their service life. The hot-dip galvanization process uses zinc, a naturally occurring element that is 100% recyclable without loss of quality. Additionally, the long lifespan of these tubes reduces the demand for raw materials and energy associated with manufacturing new products, further minimizing their environmental footprint. For projects aiming to achieve green building certifications such as LEED, these sustainable attributes can contribute to earning points and demonstrating a commitment to eco-friendly practices.

Quality control is a cornerstone of ASTM A500 GrB tube production, ensuring that each unit meets the highest standards of performance and reliability. Manufacturers subject the tubes to rigorous testing, including tensile strength tests, yield strength tests, and dimensional checks, to verify compliance with ASTM specifications. The hot-dip galvanization process is also closely monitored to ensure uniform coating thickness and adhesion, with inspections conducted using methods such as magnetic thickness gauging and visual examination. These quality assurance measures provide users with confidence that the tubes will perform as expected in their intended applications, reducing the risk of failures and ensuring safety.

In conclusion, ASTM A500 GrB hot-dip galvanized square tubes in the 2x2 inches x 14 Gauge (50x50x2.0mm) size are a superior choice for projects requiring strength, durability, and corrosion resistance. Their adherence to American standards ensures consistent quality and performance, while their versatile design makes them suitable for a wide range of applications in construction, industry, and architecture. The combination of ASTM A500 Grade B steel and hot-dip galvanization delivers a product that can withstand harsh environments, reduce maintenance costs, and provide long-term value. Whether used in structural frameworks, machinery, or architectural features, these tubes offer the reliability and efficiency that professionals demand. For those seeking a high-performance, sustainable, and cost-effective structural solution, ASTM A500 GrB hot-dip galvanized square tubes are an excellent investment.

More Products

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.