National standard hot-dip galvanized square steel tubes

Category:

Summary description:

Keywords:

Details

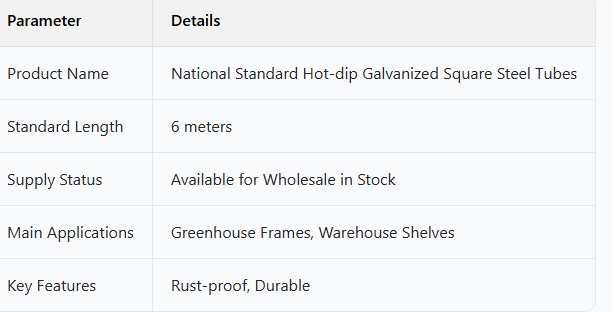

National Standard Hot-dip Galvanized Square Steel Tubes: A Reliable Solution for Multiple Applications

In the construction and industrial sectors, the demand for high-quality, reliable materials is unwavering. National standard hot-dip galvanized square steel tubes, with their standard 6-meter length, ready-to-ship availability, and exceptional rust-proof and durable properties, have emerged as a cornerstone for numerous applications, particularly in greenhouse construction and warehouse shelving. These tubes not only adhere to strict national quality standards but also offer a combination of performance, convenience, and cost-effectiveness that makes them a preferred choice for professionals and DIY enthusiasts alike.

The adherence to national standards is the first and foremost advantage of these square steel tubes. These standards encompass various aspects, from the chemical composition of the steel to the thickness and uniformity of the galvanized coating. By complying with these regulations, the tubes ensure consistent quality across different batches. This means that regardless of when or where the tubes are purchased, users can have confidence in their strength, durability, and resistance to environmental factors. The national standardization also simplifies the selection process, as architects, engineers, and contractors can easily identify and specify the exact requirements for their projects, reducing the risk of errors and ensuring compatibility with other construction materials.

The hot-dip galvanization process is what truly sets these square steel tubes apart in terms of durability. During hot-dip galvanization, the steel tubes are immersed in a bath of molten zinc at high temperatures. This process creates a metallurgical bond between the zinc and the steel, resulting in a thick, continuous, and highly adherent zinc coating. The zinc layer acts as a sacrificial barrier, protecting the underlying steel from corrosion. Even if the surface of the tube is scratched or damaged, the zinc will corrode preferentially, safeguarding the steel and extending the lifespan of the tube. This makes the tubes ideal for outdoor applications, such as greenhouse frames, where they are constantly exposed to moisture, sunlight, and temperature fluctuations. In contrast, non-galvanized or less-protected steel would quickly succumb to rust and degradation under such conditions, leading to structural failures and costly replacements.

The standard 6-meter length of these tubes offers significant practical benefits. In construction projects, having a standardized length simplifies the planning and cutting process. For greenhouse construction, 6-meter tubes can be used as primary structural elements, such as main beams and columns, without the need for excessive splicing, which can weaken the structure. In warehouse shelving, these lengths can be easily adapted to create stable and efficient storage systems. The uniform length also makes transportation and handling more convenient. They can be loaded onto trucks in an organized manner, reducing the risk of damage during transit. Moreover, the availability of these tubes in stock for wholesale means that projects can start promptly without the delays associated with waiting for custom orders or material fabrication. This quick access to materials is crucial for meeting project deadlines and maintaining the smooth flow of construction or industrial operations.

The applications of national standard hot-dip galvanized square steel tubes in greenhouse frames and warehouse shelves are extensive and impactful. In greenhouse construction, the tubes form the backbone of the structure, providing the necessary support to withstand various external forces, including wind, snow, and the weight of the covering materials. Their rust-proof nature ensures that the greenhouse remains functional for years, even in humid and corrosive environments. For example, in regions with high rainfall or near coastal areas where salt-laden air can accelerate corrosion, these galvanized tubes offer long-term protection, reducing maintenance costs and ensuring continuous crop production.

In the realm of warehouse shelving, the durability and strength of these tubes are equally essential. Warehouses often store heavy and bulky items, and the shelving systems need to be robust enough to bear significant loads. The square shape of the tubes distributes weight evenly, enhancing the stability of the shelves. Their rust-proof property is also valuable in warehouse environments, where moisture from condensation or cleaning operations can pose a threat to the integrity of the shelving. By using these galvanized square steel tubes, warehouse operators can create reliable, long-lasting storage solutions that optimize space utilization and ensure the safety of both goods and workers.

Furthermore, the versatility of these tubes extends beyond greenhouse and warehouse applications. They can also be used in a wide range of other projects, such as industrial fencing, outdoor signage structures, and even in the construction of temporary buildings. Their ability to combine strength, durability, and ease of installation makes them a multi-purpose material in the construction and industrial sectors.

In conclusion, national standard hot-dip galvanized square steel tubes, with their 6-meter standard length, ready availability for wholesale, and outstanding rust-proof and durable features, represent a reliable and practical solution for various applications. Whether it is for building a robust greenhouse to support agricultural production or creating efficient warehouse shelving for industrial storage, these tubes meet the highest quality standards while offering long-term performance and cost savings. As the construction and industrial industries continue to evolve, the demand for such high-quality materials is only set to increase, solidifying the importance of national standard hot-dip galvanized square steel tubes in modern projects.

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.