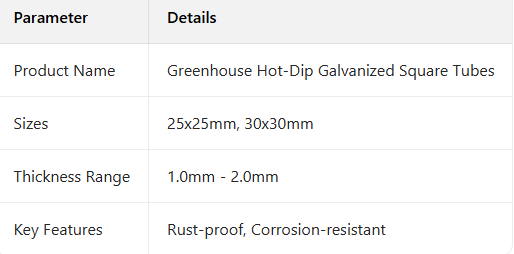

Greenhouse hot-dip galvanized square tubes 25x25mm / 30x30mm 1.0-2.0mm Rust-proof and corrosion-resistant

Category:

Summary description:

Keywords:

Details

Greenhouse Hot-Dip Galvanized Square Tubes: The Backbone of Durable Agricultural Structures

In the dynamic world of agriculture, where environmental conditions can be harsh and unpredictable, the choice of structural materials directly impacts the longevity and efficiency of greenhouse operations. Among the array of options available, hot-dip galvanized square tubes in sizes 25x25mm and 30x30mm, with thicknesses ranging from 1.0mm to 2.0mm, stand out as a cornerstone of reliable, long-lasting greenhouse frameworks. Designed to thrive in moisture-rich, temperature-fluctuating environments, these tubes combine robust structural integrity with exceptional resistance to rust and corrosion, making them an indispensable asset for modern farmers and horticulturists.

At the core of their appeal is the hot-dip galvanization process, a time-tested technique that involves immersing steel tubes in a bath of molten zinc. This process creates a metallurgical bond between the zinc and the steel, forming a protective coating that acts as a shield against the elements. Unlike paint or other surface treatments that merely sit on the steel’s surface, the zinc coating in hot-dip galvanized tubes becomes an integral part of the material, ensuring uniform protection even in hard-to-reach areas—such as corners, welds, or crevices—that are prone to corrosion. For greenhouses, which are constantly exposed to high humidity, irrigation water, and occasional rainfall, this level of protection is non-negotiable. It prevents rust from weakening the structure over time, reducing the need for frequent repairs and extending the greenhouse’s operational lifespan significantly.

The dimensional versatility of 25x25mm and 30x30mm square tubes caters to the diverse needs of greenhouse design. The 25x25mm variant is ideal for lighter structural components, such as secondary supports for cladding, ventilation systems, or trellises for climbing plants like tomatoes or cucumbers. Its compact size allows for flexible installation in areas where space is limited, while its square shape ensures stable connections with brackets, bolts, or welding. On the other hand, the 30x30mm tube is engineered for heavier loads, serving as primary frames, column supports, or roof trusses. This larger profile distributes weight more evenly across the structure, enabling the greenhouse to withstand external pressures such as wind, snow, or the weight of hanging equipment like grow lights or irrigation pipes.

The thickness range of 1.0mm to 2.0mm further enhances the adaptability of these tubes. For small-scale greenhouses or temporary structures, the 1.0mm thickness offers a cost-effective solution without compromising on basic durability. It provides sufficient strength to support lightweight coverings like polyethylene film or polycarbonate sheets, making it a popular choice for hobby gardeners or seasonal crop growers. In contrast, the 2.0mm thickness is tailored for commercial greenhouses or those located in challenging climates. Its increased density adds rigidity, allowing the structure to endure extreme weather conditions—from strong gales to heavy snowfall—while maintaining structural stability. This flexibility in thickness ensures that farmers can select the exact specification that aligns with their budget, climate, and crop requirements.

Beyond their structural and protective benefits, these hot-dip galvanized square tubes contribute to the overall efficiency of greenhouse operations. Their smooth, zinc-coated surface resists the buildup of dirt, algae, or mineral deposits from irrigation water, reducing the need for regular cleaning and maintenance. This low-maintenance attribute is particularly valuable in large commercial setups, where time and labor are precious resources. Additionally, the square shape of the tubes simplifies assembly and customization. Unlike round tubes, which can shift or rotate when fastened, square tubes provide flat, stable surfaces for attaching brackets, shelves, or plant supports. This ease of installation accelerates the construction process, allowing farmers to set up or expand their greenhouses quickly and efficiently.

Durability is a defining feature that sets these tubes apart from alternative materials. Traditional steel tubes, if uncoated or painted, are susceptible to rust when exposed to the high humidity inside greenhouses. Rust not only weakens the structure but can also contaminate soil and water, posing risks to plant health. Hot-dip galvanized tubes eliminate this concern: the zinc coating acts as a sacrificial layer, corroding slowly over time to protect the underlying steel. In typical greenhouse conditions, this coating can last for 15 to 20 years, far outperforming painted or electroplated alternatives. This longevity translates to long-term cost savings, as farmers avoid the frequent replacement costs associated with inferior materials.

Environmental sustainability is another key advantage. Hot-dip galvanization is a highly recyclable process, with zinc being one of the most recycled metals globally. At the end of their lifespan, these tubes can be melted down and reused, minimizing waste and reducing the carbon footprint of agricultural operations. Furthermore, the durability of the tubes reduces the demand for new steel production, conserving natural resources and energy. For farmers aiming to adopt eco-friendly practices, these tubes align with sustainable agriculture goals, supporting both crop productivity and environmental stewardship.

In summary, greenhouse hot-dip galvanized square tubes in 25x25mm and 30x30mm sizes, with thicknesses from 1.0mm to 2.0mm, represent a perfect fusion of strength, protection, and practicality. They address the unique challenges of greenhouse environments—moisture, temperature fluctuations, and external pressures—while offering flexibility in design and cost. Whether for a small backyard greenhouse or a large-scale commercial facility, these tubes provide a reliable foundation that ensures crops are grown in a stable, protected environment. Their rust-proof and corrosion-resistant properties, combined with their structural versatility, make them an investment that pays dividends in long-term durability, operational efficiency, and sustainable agricultural success. For anyone seeking to build or upgrade a greenhouse, these hot-dip galvanized square tubes are not just components—they are the backbone of a thriving, resilient growing operation.

Message

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD. SEO 【Business license】

All Rights Reserved Copyright © RIZHAO STEEL HOLDING GROUP CO.,LTD.